For this reason, when a neophyte asks if it is better to drill with the lathe, by hand or with a drill press, I answer: what you do best. In the same way, to obtain the final shape of the pipe, some people prefer the belt-sander, others the rasps and others use knives or sandpaper stripes.

Inevitably, at the beginning, the choice of the process mainly depends on the school where one has grown up. For instance, I learned drilling with a lathe for metals, but it might happen that the briar needs a different approach. The shape of the block, the particular course of the veining, your research for an audacious shape or simply, the numerous defects on the wood surface might lead you to choose “hand-drilling.” That’s where I have had an exceptional Maestro: Gabriele Dal Fiume.

Anyway, for a craftsman, learning new things from different schools has always to be a fascinating experience, otherwise he ends up making always the same tiny golden fishes, as Aureliano Buendia did in One Hundred Years of Loneliness.

For me, the entire process begins on a comfortable sofa, drawing shapes, details or whole pipes. I consider this time as an essential premise of the action that will stem from it: getting the imagination up by creating a graphic history of my thought.

Once a good number of projects has been gathered, I start choosing the suitable briar blocks. Imagination is still in action, since you have to “see” the future grains of the pipe, which is one of the most difficult steps in the entire process and it distinguishes the great Masters from all others. Taking inspiration from the shape of the briarroot and from its grains to design a pipe means also reducing the waste of material to the bare minimum. This ability is a gift or a skill that needs many years of practice to be acquired but shows anyhow the profound respect a pipe maker must have for the briar root.

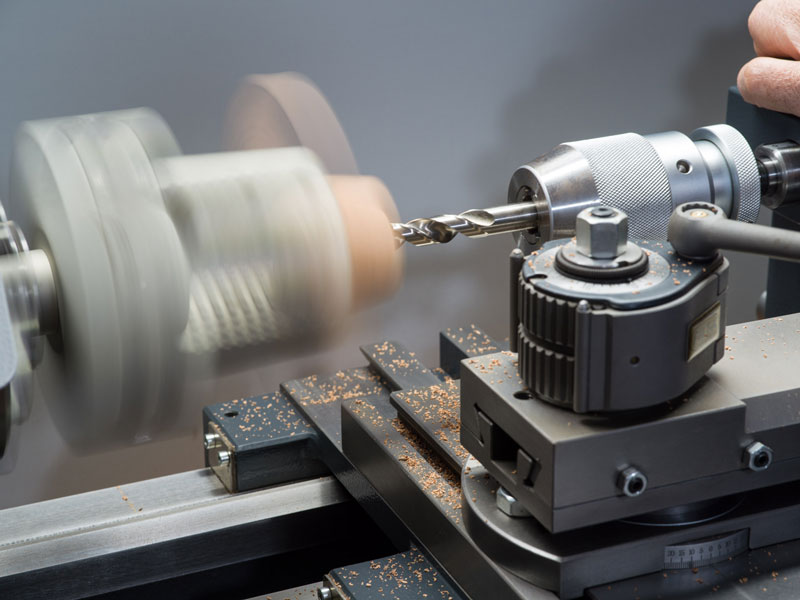

Once the blocks for each project are chosen, I drill them on the lathe, shape them roughly with a sand disk and hand-finish them off with the help of rasps, abrasive sandpapers, belt sander, sanding pads, knives or dremel, depending on the need.

I find extremely useful to work simultaneously on several pipes, a precious advice that Mimmo Romeo gave me the first time we met. Actually, if you work on a single pipe at a time, you cannot be detached enough from the project to see it “from the outside” and a certain compulsiveness prevails. The research of quality requires that you learn how to make effective use of the obsessive energy that is typical of a craftsman: in compulsiveness you can no longer distinguish between “good” and “a little less than good.” Therefore, moving from a pipe to another becomes a way to manage such energy, take a certain distance and identify more clearly the possible evolution from the original design, hardly ever definitive as you thought at the beginning.

I realise handmade stems for each pipe. I rarely dye, but I like to use oil to accentuate the contrast. After drilling and defining the mortise on the lathe, I model the shape with abrasive disk and large files, and then I move on to finishing with medium and fine grain files, small files and scalpel. Then the craved moment arrives at last: it’s the phase of buffing and waxing with cotton wool pads. The pipe acquires light, the grains are enhanced so that you wonder how you could realise such a beautiful object from a mere wood block. A last look, hardly ever completely satisfied, as creativity doesn’t foresee such an emotion, and the pipe ends up in its bag, ready to be offered to anyone who wants to smoke it.